Why do Water in Oil Monitors go under different names?

Online Water-in-Oil Sensors are essential for detecting and monitoring water contamination in oil and fuel systems. However, depending on the industry or application, these instruments are often referred to by different names.

Why So Many Different Names?

Online Water in Oil Sensors are often given different names. Sometimes they are referred to as water sensors, water-cut analyzers, bs&w probes, moisture sensors and moisture meters. The name given to the product often depends on which industry is using them and what terms they are familiar with. Some operators also use the EASZ products for detecting water in fuel lines.

Is It Moisture or Is It Water?

The answer to this may not be so clear when considering that some chemicals are designed to be either hydrophilic or hydrophobic. We are measuring small or large changes in the dielectric constant of a liquid. The instrument will detect changes in H2O content, whether the H2O in oil is dissolved, emulsified or free.

The video above shows a typical application where the instrument is referred to as a ‘moisture in oil meter.’ At the beginning of the video, however, it is actually detecting a change in the free water content during tank truck unloading

What is an Online Water in Oil Monitor?

An online water in oil monitor or water sensor measures everything that passes through a process pipe. An offline instrument determines the water content of an oil by measuring a small volume (spot sample) in a laboratory e.g. centrifuges, karl fischer etc.

Why Online Monitoring is Important

- Water contamination in oil can cause corrosion, oil degradation, equipment failure, and costly downtime. Relying solely on spot sampling may leave operators blind to water events that occur between tests.

What are the benefits of continually monitoring oil and fuel?

Spot sampling for water in oil is not able to capture every “water event.” A water event could simply be small clouds of water droplets travelling down a pipe but never detected by a typical moisture sensor. Our water in oil monitors will not only give an indication of the dissolved water in oil but also capture events e.g. free water.

With an online water-in-oil monitor, operators benefit from:

Early detection of water ingress from condensation, cooler leaks, or process faults.

Continuous protection of engines, turbines, compressors, and pipelines.

Improved efficiency by reducing the need for frequent manual sampling.

Reliable compliance with quality and safety standards.

Selecting the Correct Water in Oil Monitor

General Industry

These versions of our products do not require Ex Certification and are installed in non-hazardous areas. The standard connections are normally either screwed connections e.g. NPT, BSP, or flanged units to ANSI, DIN, JIS. Other connections are also available e.g. SAE for hydraulic oil and sanitary connections for the food and drink industry.

Industries and Applications we serve include:

- Lubrication systems

- Hydraulic systems

- Oil and fuel applications in ships

- Power Plants

- Pulp and paper

- Steel Mills

- Food Industry

- Compressor Oil

- Turbine Oil

Example Applications:

Our water-in-oil monitors are trusted in diverse industries worldwide, where oil contamination can mean downtime, revenue loss, or product failure. Here are a few key examples of how they are applied:

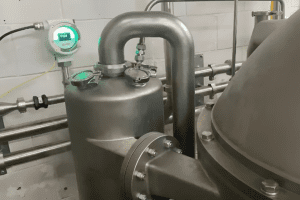

Fish Oil Plant

In fish oil production, maintaining product purity is essential for both quality control and regulatory compliance. Even small amounts of water can lead to:

- Degradation of oil quality

- Reduced shelf life

- Unwanted microbial growth

Our monitors provide continuous, real-time detection of water ingress, ensuring that only high-quality oil reaches the market.

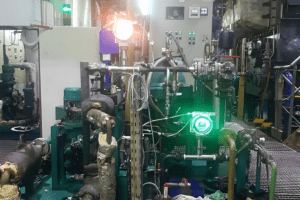

Ship Propulsion System

Marine engines and propulsion systems operate under harsh, moisture-prone conditions where water contamination is a constant risk. Problems caused by water in oil include:

- Bearing wear and corrosion

- Reduced lubrication performance

- Fuel adulteration risks during bunkering operations

- Our rugged, stainless-steel monitors are designed to perform reliably even in offshore and marine environments, helping operators avoid failures and improve vessel reliability.

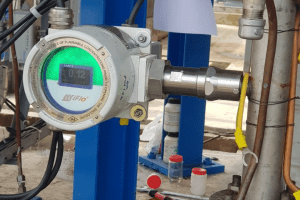

Diesel Power Station

Diesel engines are highly sensitive to water contamination in both fuel and lubrication systems. If undetected, water can cause:

- Poor combustion efficiency

- Corrosion and wear in injectors and pumps

- Unexpected downtime and costly repairs

By installing online monitors, operators gain round-the-clock protection, allowing them to act before water-related issues escalate.

Food Grade Oil Plant

In the food and beverage industry, oils used in production and processing must meet strict safety and hygiene standards. Water contamination not only compromises product integrity but can also lead to:

- Regulatory non-compliance

- Equipment damage in food-grade systems

- Costly product recalls

Our sanitary connection options ensure safe, hygienic integration into food processing lines while providing accurate monitoring.

Oil and Gas Industry

Offshore and onshore operations face constant risks of water ingress, whether in crude oil pipelines, fuel systems, or lubrication circuits.

Our products are available in screwed and flanged connections. Fully stainless steel for offshore platforms

- Offshore oil and gas platforms

- Oil and Condensate pipelines

- 2 and 3 stage oil separation systems

- LACT systems

- Custody Transfer Metering and Sampling

- Well Testing

- Fuel Transfer Systems

- Crude Oil Batching

- Multiphase Separators

Crude Oil Sampling System

Pipeline Water Cut

Units With Mixers

More Than One Option

Our Water in Oil Monitors have units specifically designed to meet different needs.

- EASZ-1 General Range Water in Oil Monitor

- EASZ-2 Low Range Precision Measurements in Lower Concentrations of Water

- EASZ-2 Full Range Wide Range Oscillator for 0-100% water in oil/ oil in water

EESIFLO TECHNOLOGIES INC.

ADDRESS: 3928 US-80, Rayville, LA 71269

CALL: +1(318) 614-3971

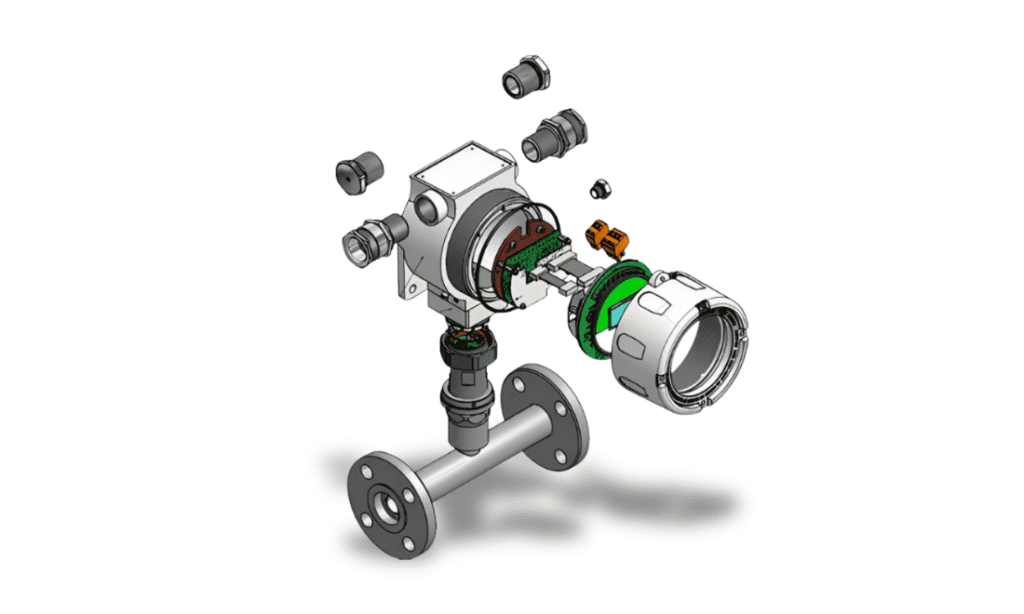

Do you require an insertion watercut meter?

Look no further. EESIFLO manufactures it’s own unique range of Insertion Watercut probes. These are ideal for applications where inserting a probe into a crude oil pipeline is preferred.

What information is needed to size an insertion watercut meter?

Let us know the pipe sizes , pressures, temperatures and the take off port height, so that we can establish what the throw length is. Our insertion meters are typically manufactured in 316L and have been designed to insert into large crude oil pipes starting from 6 inches.