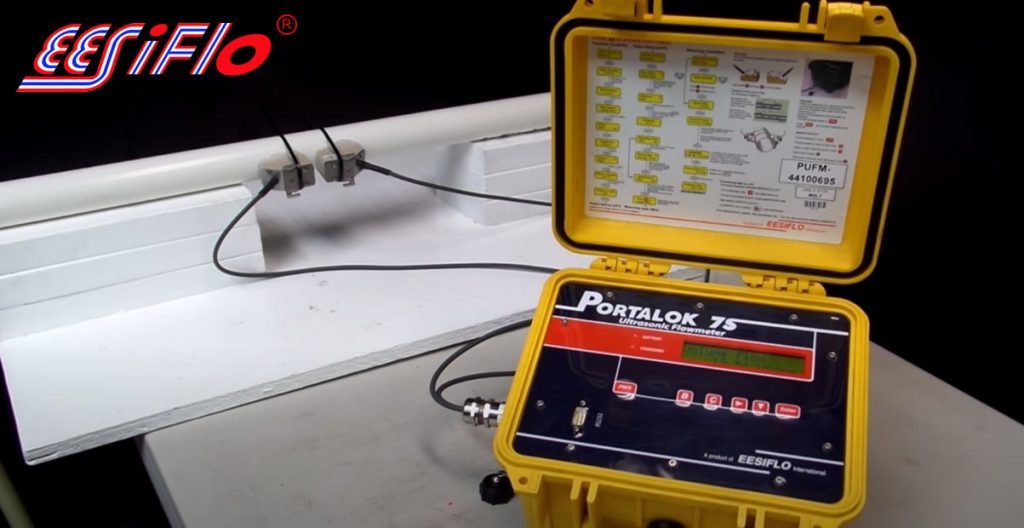

Portable Ultrasonic Flow Meter 7SE

Strap on Flow Measurement without cutting the pipe

Portable Clamp on Ultrasonic Flowmeter

Our range of non-invasive flowmeters utilises ultrasonic technology for the accurate flow measurement of liquids in full pipes. The portable device has been designed to meet the needs of the Service/Maintenance and Commissioning Engineer wishing to check the flow rate of liquids at different locations in the plant. The set-up of the unit is simple and user friendly in order to obtain the required flow information in minutes.

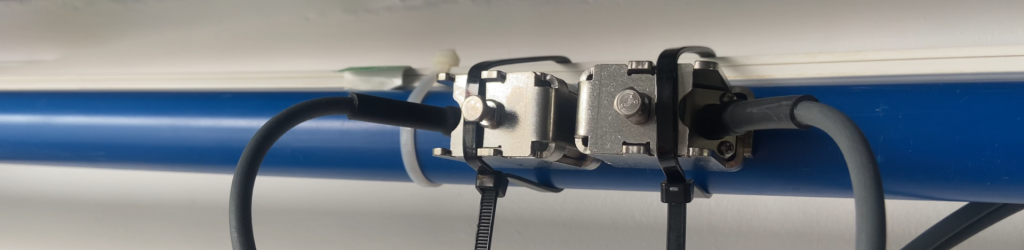

The measurement of flow is based on the principle that sound waves are influenced by a flowing medium. Measurements are made by penetrating the pipe with ultrasound and subsequently time differences, frequency variations and phase shifts of the ultrasonic signals are evaluated. The ultrasonic sensors are clamped onto the outside of the pipe, thus eliminating the need to dismantle the pipework and interrupt the process. The unit can be applied to any type of standard pipe carrying clean or dirty liquids.

Sensors can be clamped onto any kind of pipe within minutes. These flow sensors are manufactured for conditions faced in industrial plants and outdoors. Sensors are carefully paired and are accurate down to zero flow and up to all velocities.

When fully closed, the flow transmitter is completely weather proof. The unit has a long battery life and options of additional power sources (battery banks) for extended measurements that may go on for weeks.

EESIFLO is trusted name in clamp on flow measurements for liquids with thousands of successful installations around the globe. The Portalok series of clamp on flow meters has been tried and tested for over a decade from almost every imaginable type of user. We manufacture highly reliable instruments designed for ease of use, accurate and repeatable measurements and product longevity.

FEATURES

- Portable dual mode flowmeter able to measure clean and dirty liquids without changing sensors

- Easy to install clamp-on sensors with no process interruption

- Non-invasive flow measurement of liquids, no pipeline disturbance, no pressure loss

- Suitable for all commonly used pipe materials

- Optional thickness gauge

ADVANTAGES

- Low installation effort and costs

- One meter for most liquid applications

- Measurement is independent of fluid conductivity and pressure

- No pressure loss, no possibility of leakage

- Retrospective installation for existing plants possible

- No cutting of pipes necessary, no interruption of process, no plant shut down

- No additional fittings for maintenance required

- Hygienic measurement, no risk of contamination, suitable for ultra clean liquids

- No contact with medium, no risk of corrosion when used with aggressive media

- Cost advantages when used with large diameter pipes, high pressure systems, etc.

The EESIFLO 7SE series is a tried and tested highly accurate ultrasonic flow meter designed to measure flow rates on almost any kind of liquid application. It is extremely easy to set up the flow meter and in some cases (with magnetic clamping fixtures) it should not take more than 1 minute.

The 7SE series is a powerful device designed to measure not only in general applications but also in small and large pipes . The unit is available for rental and purchase through most EESIFLO office locations and also through EESIFLO distributors. The sensors have been carefully designed to eliminate errors caused by changing pipe temperatures and the diurnal effect.

It is not uncommon that long term measurements are required for flow balancing a liquid system. In these cases, the clamp on ultrasonic flow meter needs to be left unattended for long periods of time and data needs to be retrieved. It is important that battery power is maintained throughout this time.

Information on integrated operating times without additional back up batteries

Without outputs and backlight, -continuous measurement: > 48 Hours -low power mode:•7 days measuring interval: 1min•30 days (measuring interval: 10 min•180 days measuring interval: 30 min•270 days measuring interval: 60 min-Minimum night flow mode: •14 days (4-hour continuous measurement per 24 hours)•30 days (2-hour continuous measurement per 24 hours)•60 days (1-hour continuous measurement per 24 hours)

Suitability of Clamp on Flow Meters for your application

EESIFLO takes a conservative approach when applying clamp on flow measurement techniques. The following questions might need to be asked when considering this technology

- What accuracy is required at low velocities?

- Is there a reasonable straight length of pipe available?

- How quickly can your operators learn to use the flow meter with a level of confidence?

- How reliable are the measurements and how can a measurement be verified?

With the above in mind, it is a good idea to consult one of our specialists to see the feasibility of using clamp on technology . EESIFLO has a global presence and we will be glad to assist any user who would like to know if this technology is right for your organisation.