What is a Full-Cut Water-Cut Meter?

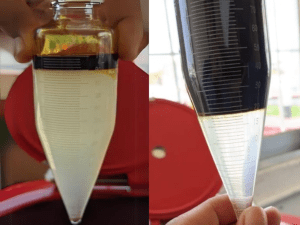

Full-Cut Water-Cut Meter is a device designed to measure the percentage of water in crude oil—or crude oil in water—across the entire 0–100% range.

Complete Range Water-Cut Analyzer for Crude Oil

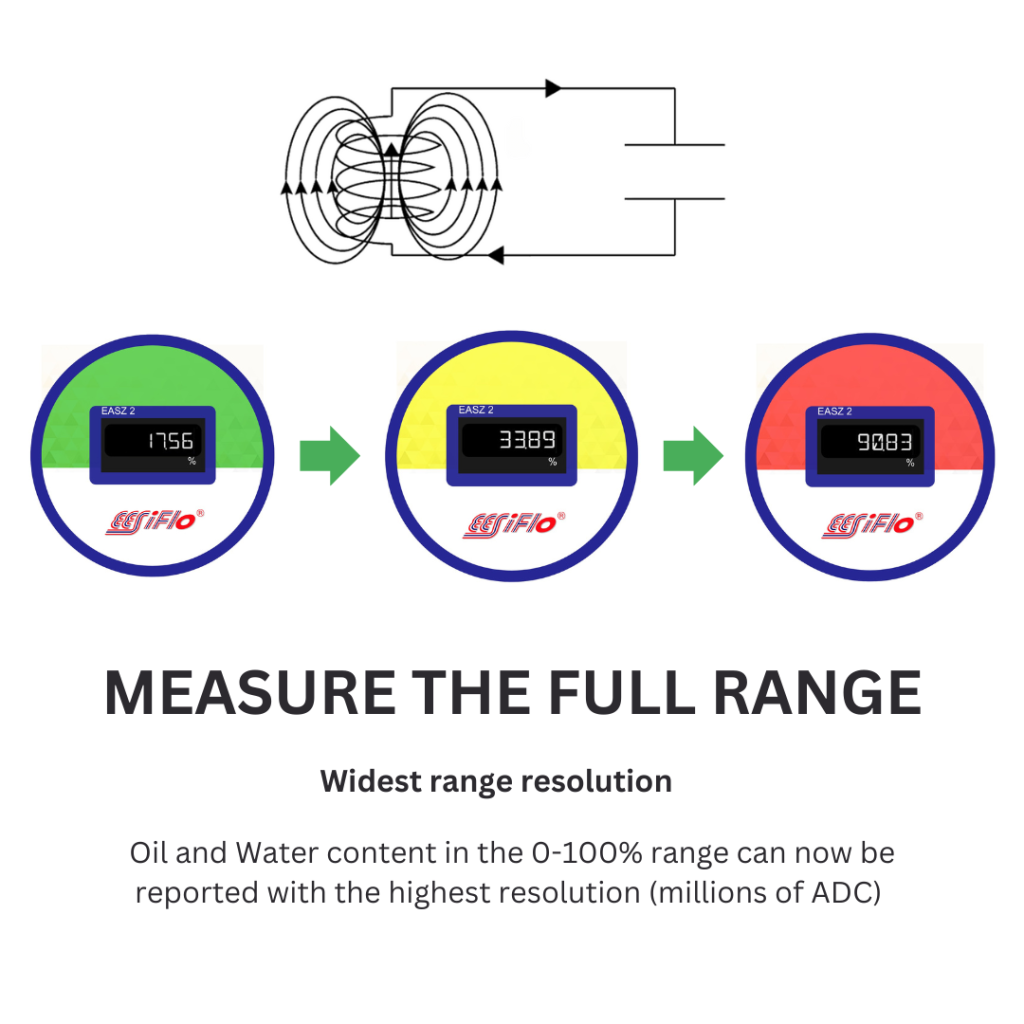

This EESIFLO Full Range (FR) version of the EASZ-2 uses a wide range oscillator to measure water content in the 0-100% range. It uses modern circuits, components and software to improve the signal processing so that quasi signals are filtered out. This technology is extremely useful for two-phase and three-phase crude oil separators in oil fields at initial production stages and further downstream separation, transport, metering and transfer of crude oil products.

Light crude, medium crude and heavy crude oil 0-100% Inline Water in Oil Measurements in oil exploration and production.

Full-Cut Water Cut Transmitter

The Easz-2 Full range unit (FR) uses a wide range oscillator which enables it to measure a volume consisting of 100% water or 100% oil as well as fractions of water/oil. It was initially developed for operators who were unsure at the initial stages what to specify as a range e.g. 0-1% water in oil, 0-10%, 0-25%, 0-50% and even 0-100%. With such wide range possibilities, it is more convenient for operators to reconfigure the same instrument for an alternative range if the actual ranges in the process differ from the ordered range. Over the years, our experience has shown that very often those who have specified a water in oil range did not have proper access to important details regarding water/oil ranges. If the range is unknown, it is possible to reconfigure the instrument to work within any range.

EASZ-2 Full Cut

The EASZ-2 Full-Cut offers a user-friendly solution designed for seamless installation and operation in oilfield applications, combining simplicity with robust functionality. Featuring an Ex rating, it ensures safe and reliable use in environments where explosive hazards may be present.

One of its standout features is the optional Bluetooth capability, which revolutionizes the calibration process. With this feature, users can perform calibration or re-calibration wirelessly, eliminating the need to open the enclosure or manually connect to wiring terminals. This not only enhances safety and convenience but also significantly reduces downtime, making the EASZ-2 Full-Cut an efficient and reliable choice for demanding oilfield environments.

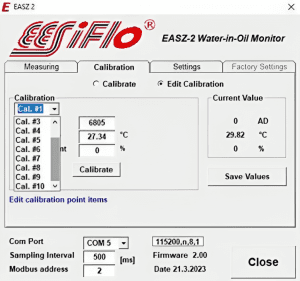

Ten Point Calibration

The ten-point calibration feature offers an advanced level of precision, providing users with the flexibility to enhance accuracy in challenging applications where the composition of the oil-water mixture is uncertain.

This capability is particularly beneficial in cases involving either the water-in-oil or oil-in-water phases, as it allows for fine-tuned adjustments to accommodate varying mixture ratios. Furthermore, the calibration process minimizes the impact of external factors such as salt content, additives, and contaminants, ensuring more reliable measurements. By addressing these potential inconsistencies, the multi-point calibration option delivers superior performance, making it an indispensable tool for complex fluid analysis and processing applications.

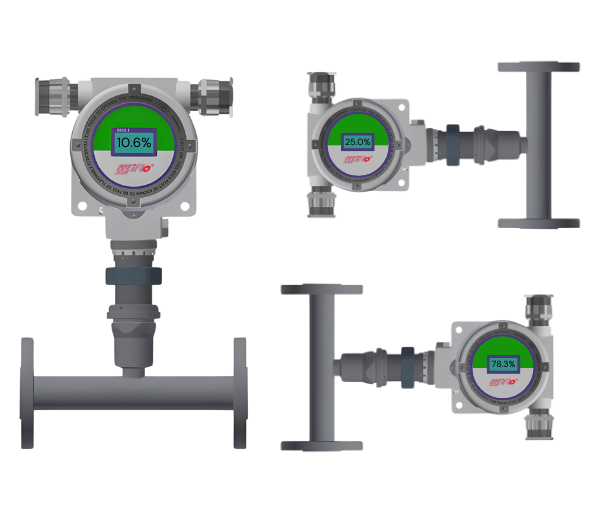

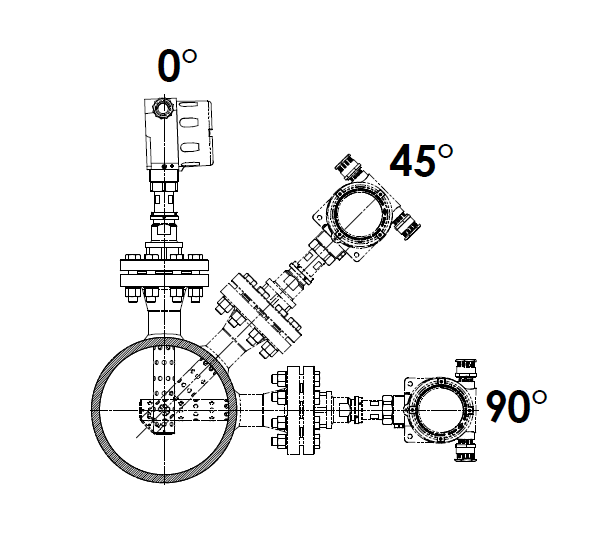

User Selectable Orientation of the Water-Cut Display

This feature was added because of users requesting an option be available to change the orientation of the EASZ-2 due to various piping configurations. The cut meter display can be rotated 90° either clockwise or anti-clockwise from it’s default horizontal installation position. The units can also be pre-ordered to the most convenient display position before shipment.

Replacement of legacy type Water-cut meters

This product is an outstanding solution for new oil field developments, whether located onshore or offshore. Designed with versatility and reliability in mind, it is certified explosion-proof to ensure safe operation in hazardous environments. Additionally, it is available in both standard sizes and customizable lengths or dimensions, allowing it to seamlessly replace existing devices and meet specific operational requirements. Its robust construction and adaptable design make it an essential component for modern oil field applications.

APPLICATIONS

- Real-time production management, optimization, and automation

- Well head: automatic well test, multiphase separators

- Crude oil batching

- Monitoring crude oil separator retention time

EESIFLO TECHNOLOGIES INC.

ADDRESS: 3928 US-80, Rayville, LA 71269

CALL: +1(318) 614-3971

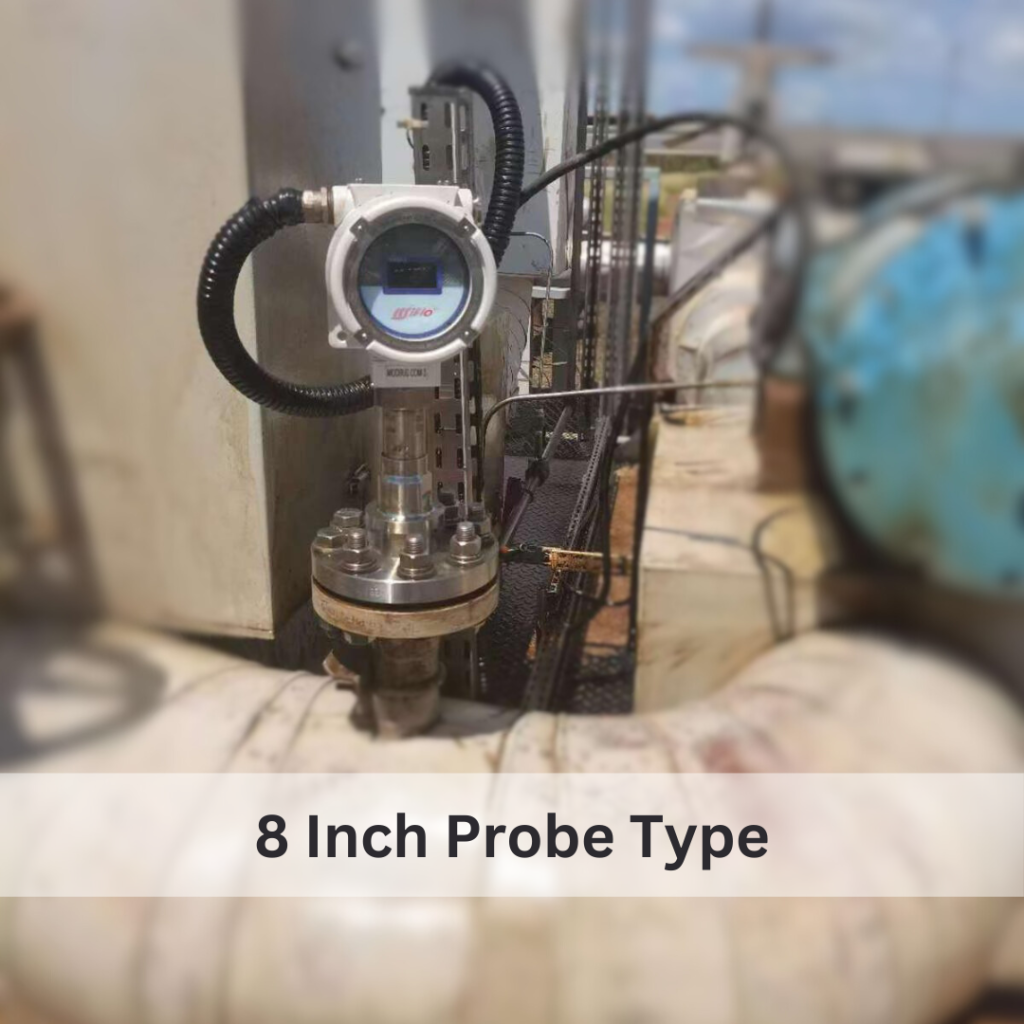

Do you require an insertion watercut meter?

Look no further. EESIFLO manufactures it’s own unique range of Insertion Watercut probes. These are ideal for applications where inserting a probe into a crude oil pipeline is preferred.

What information is needed to size an insertion watercut meter?

Let us know the pipe sizes , pressures, temperatures and the take off port height, so that we can establish what the throw length is. Our insertion meters are typically manufactured in 316L and have been designed to insert into large crude oil pipes starting from 6 inches.