2-Wire Loop Popwered Water-Cut Monitor

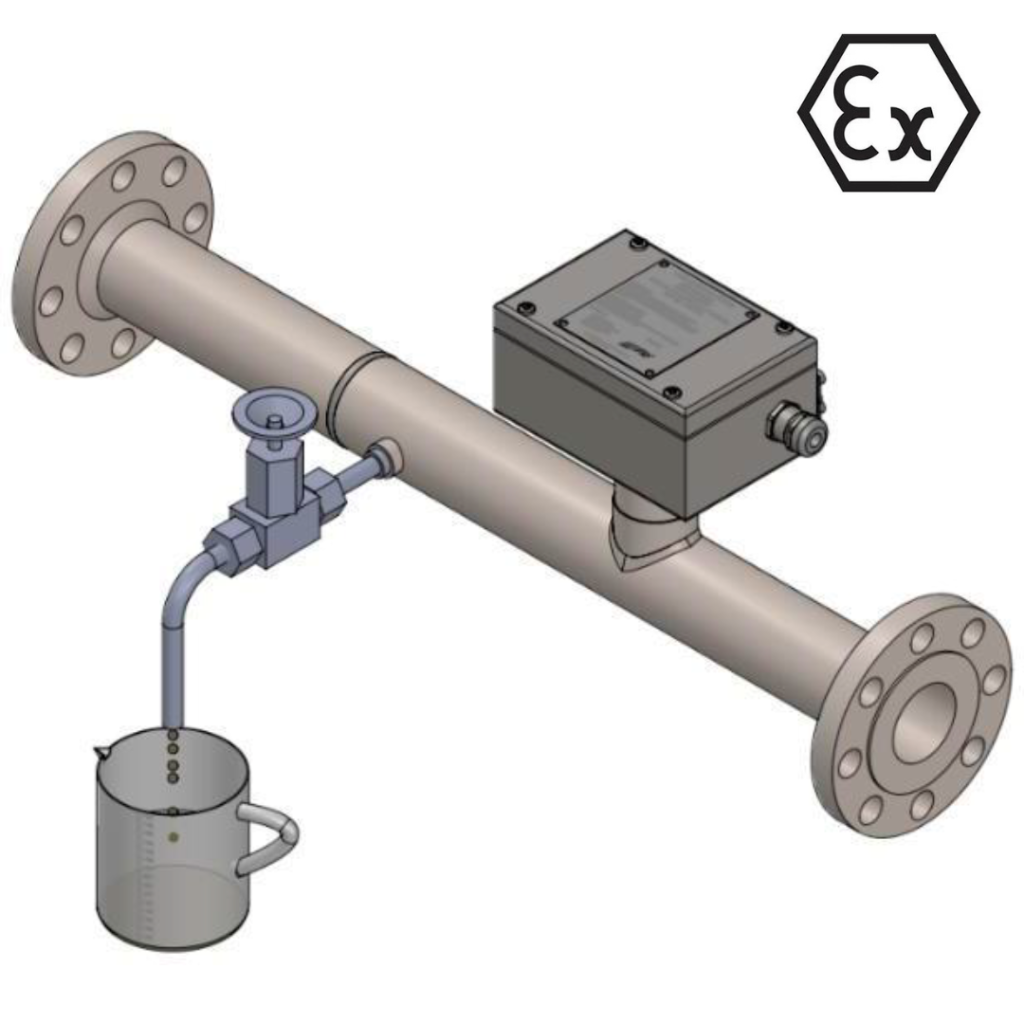

This product is a 2-wire loop powered BS&W water-cut probe which is installed directly into a crude oil piping system.

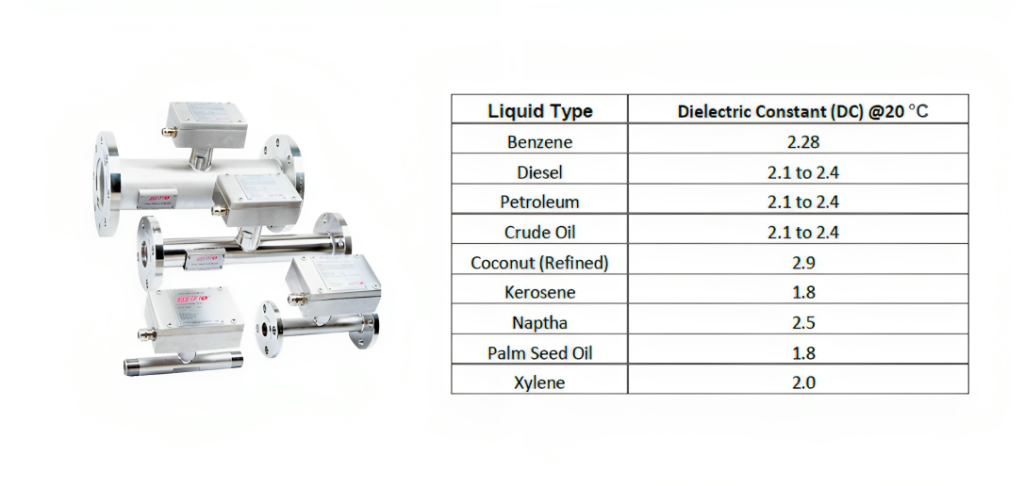

It can also report and detect free water variations in any hydrocarbon e.g gasoline, diesel, naptha. System integrators can find information on installation, wiring and how it works by referring to the EASZ-1 manual Rev.2.0

Watercut meters measure the H2O content (percentage) of crude oils and similar liquids in a flowing stream. The American Petroleum Institute refers to this as OWD or On-Line Water Determination.

Ideal for applications for first, second and third stage crude oil separators, crude oil transfer in pipelines and in tank truck terminals. The watercut is expressed as a percentage of water in the total fluid stream.

Some Application Photos

General Specifications

Operating Principle: Capacitance

Supply Voltage : 12…24 V DC, 2 Wire Loop-Powered

Power Consumption: 0.66 Watts

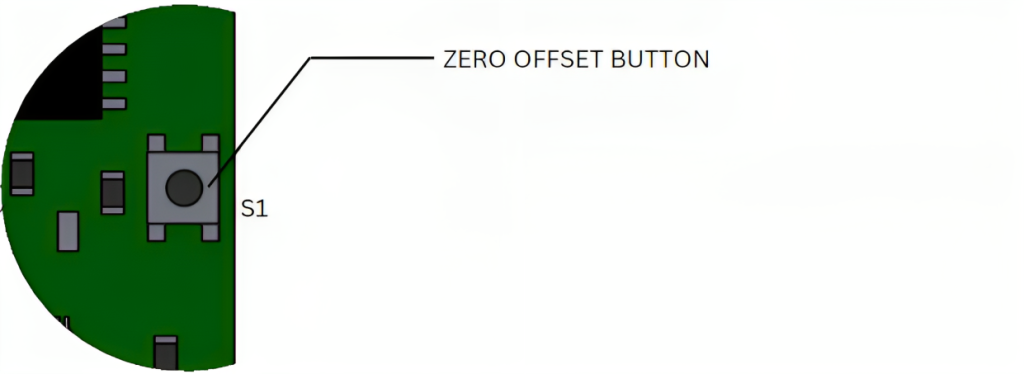

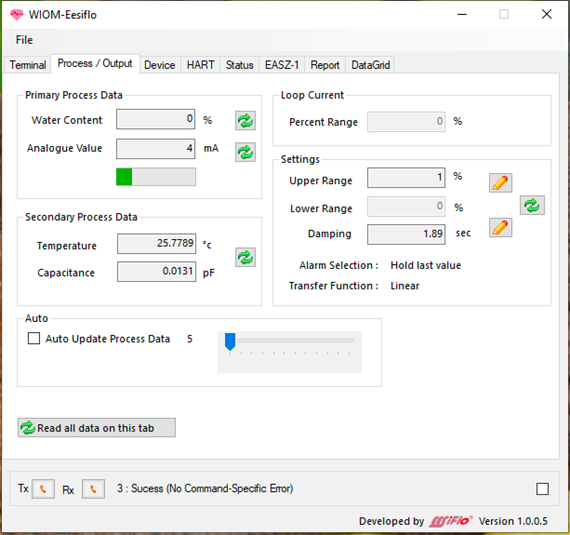

Setup and Calibration: PC Connection via USB RS-232 or RS-485 Universal HART

Electronics Enclosure: Stainless Steel 316, IP66

Ambient Temperature: -20 Celcius… 60 Celcius (-4 F… 140F)

Response Time: 1s nominal (no averaging applied) 1-2 seconds programmable averaging time

Start-Up Time: 20s Remote Display Panel or Field Type (galvanically isolated)

Process Pressure: Up to 100 Bar (1,450 Psi), higher pressure consult EESIFLO with process information

Connection Size: DN25.. DN600 (1″ Inch..24″ Inch), larger sizes consult EESIFLO

Process Connections: NPT, BSP, ANSI flanges, PN flanges, JIS flanges

Body & Sensing Element Construction Material: Stainless Steel 316/316L (Standard), NACE Compliant Optional Duplex, Monel, Hastelloy and more upon request

Seals and Spacers: PEEK

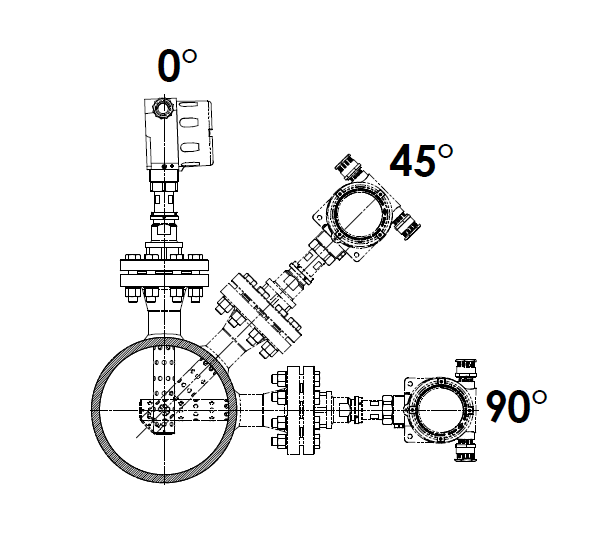

Installation: Inline or bypass setup

Approvals: Intrinsic Safety (IS) ATEX, IECEx, CSA, CE Mark

EESIFLO TECHNOLOGIES INC.

ADDRESS: 3928 US-80, Rayville, LA 71269

CALL: +1(318) 614-3971

Do you require an insertion watercut meter?

Look no further. EESIFLO manufactures it’s own unique range of Insertion Watercut probes. These are ideal for applications where inserting a probe into a crude oil pipeline is preferred.

What information is needed to size an insertion watercut meter?

Let us know the pipe sizes , pressures, temperatures and the take off port height, so that we can establish what the throw length is. Our insertion meters are typically manufactured in 316L and have been designed to insert into large crude oil pipes starting from 6 inches.